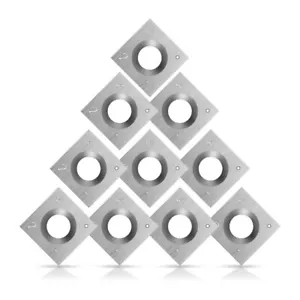

ID: 701976

SKU: 3.95E+11

Category: Hardware

Tags: 30days

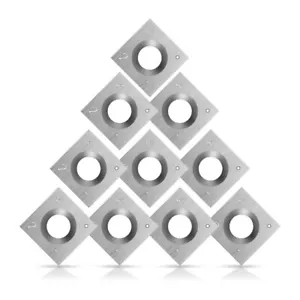

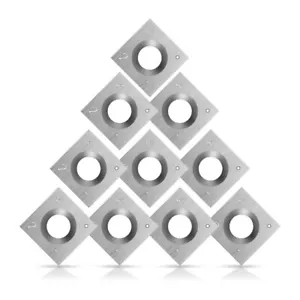

High Hardness Inserts Cutters for Precise and Stable Cutting Operations

About this item:

– Perfect for professionals looking for high-quality and durable cutting tools. – Features cemented carbide construction for exceptional wear resistance. – Ensures precise and clean cuts in various materials. – Offers a range of insert shapes and sizes to accommodate specific cutting requirements. – Provides consistent performance and long life, minimizing downtime and replacement costs.

₹14052

On preorder

Delivered in 30-60 days

On Pre-Order

Guaranteed Secure

- Guaranteed delivery

- Fast shipping

- PAN India shipping

- 100% Secure payment

- Regular orders dispatch in 48 Hours

- Pre-orders dispatch in 30-45 days

- Returns accepted

- Fast refund process

- 24/7 customer support